- inCAD Library Home

- > No.000165 Intermittent Rotary Drive by Air Cylinder

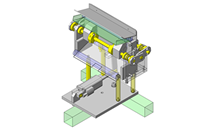

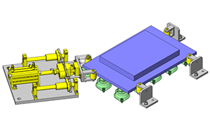

No.000165 Intermittent Rotary Drive by Air Cylinder

157

157

Single-direction 90-degree-increment rotary feed with a ratchet mechanism

Related Category

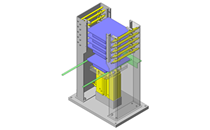

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

- Purpose

- To feed workpieces intermittently by rotating them 90 degrees at a time.

- Operation

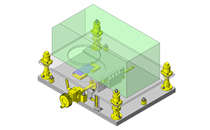

- After the rotary table is rotated 90 degrees, the thin cylinder advances the stopper pin. When the driving cylinder advances, the rotary table is kept stationary by the ratchet mechanism.

Target workpiece

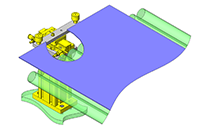

- Shape: rectangular electronic part

- Size: W15 x D40 x H30mm

- Weight: 0.019kg

Design Specifications

Operating Conditions or Design Requirements

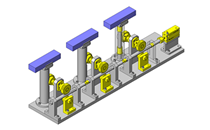

- Driving cylinder stroke: 100mm

- Positioning cylinder stroke: 10mm

- Rotary table rotation angle per cycle:90°

- Outer dimensions: width: W434 at maximum x height: H132mm

Table outer diameter: Ø300mm

Required Performance

- Load: product + pallet = 15N

Selection Criteria for Main Components

- To rotate a load of 0.024 (0.008 x 3) [N], a cylinder with an inner tube diameter of Ø20mm is selected.

Design Evaluation

Verification of main components

- Must verify the cylinder thrust to ensure the necessary rotation force can be obtained.

- Selection of driving cylinder

- Conditional value: workpiece mass: W = 0.55kg, gravitational acceleration g = 9.8m/s², friction coefficient μ = 0.0015, instroke pressure area A1 = 264mm², operating pressure P1 = 0.4MPa

- The force F1 required for rotation is obtained by F1 = W x g x μ, therefore, F1 = 0.55 x 9.8 x 0.0015 ≈ 0.008N.

The cylinder thrust (instroke) F2 is, F2 = A1 x P1 = 264 x 0.4 ≈ 105N > F1.

⇒There is no problem.

Other Design Consideration

Explore Similar Application Examples

Page

-

/

-